Product Description

Professionally promote the informationization, intelligence and unmanned construction of the furniture industry. The combination is flexible, the process is changeable, and an automated production mode that meets the needs of the customer's entire plant is created. Combine edgebanding machine with roller line to improve the automation level of the factory, get rid of the dependence on workers, and effectively improve management efficiency and production efficiency.We strive to make your production smarter, faster and more cost-feeicient with minimum human labor required.

Advantage:

- The first project successfully implemented by Chinese machinery manufacturer.

- No operator required for production rocedures. Labor cost and managing overheads are therefore greatly reduced, so is production error.

- Uninterruped production with automatic machines enables furniture makers to add extra shifts with minimum extra costs and concerns. The efficiency is also increased by at a least 25 % compared to manual operation.

- Smarter, more cost-efficient production, quicker delivery and better quality allow furniture makers for further expand production and sales, achieving higher return on capital and property.

- More individual products for end-users.

Technical Parameter

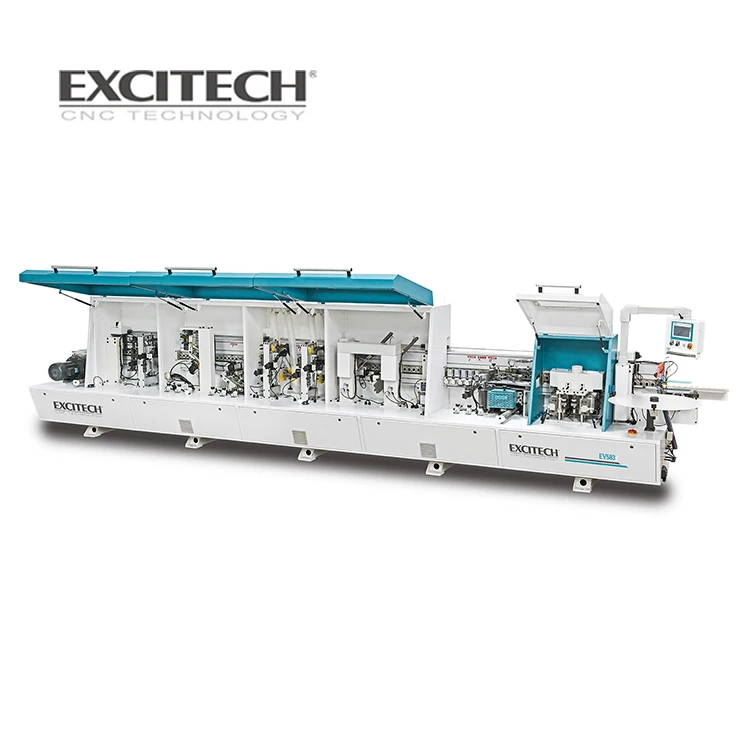

EV583 Edgebander

Pre milling,gluing,end trimming,rough trimming, fine trimming, corner trimming,scraping, off-cut, flat scraping and buffing.

|

Description

|

EV583

|

|

Working piece length

|

Min.150mm

|

Input voltage

|

380v

|

|

Working piece width

|

Min.60mm

|

Input frequency

|

50HZ

|

|

Panel thickness

|

10~60mm

|

Output frequency

|

200HZ

|

|

Edge width

|

12~65mm

|

Power

|

16.6kw

|

|

Edge thickness

|

0.4~3mm

|

Air pressure

|

0.6pa

|

|

Feed speed

|

16~23m/min

|

Machine size

|

7640*950*1608mm

|

|

Min. workpiece size

|

300*80mm /150*150mm(L*W)

|

|

Part’s name

|

Brand

|

|

Inverter

|

Delta( TAIWAN)

|

|

PLC

|

Delta( TAIWAN)

|

|

Human-machine interface

|

Delta( TAIWAN)

|

|

Temperature control module

|

AUTONICS (KOREA)

|

|

Air switch

|

DELIXI

|

|

AC contactor

|

SHIHLIN (TAIWAN)

|

|

Intermediate relay

|

Weidmuller (Germany)

|

|

Travel switch

|

America HONEYWELL

|

|

Switch button

|

German SIMENS

|

|

High-speed motor for end trimming

|

CHANGLONG( custom)

|

|

Pneumatic components

|

TAIWAN AirTAC, Japan SMC

|

Power Roller: 2000*1350mm+ 9000*1350mm

Air Table: 1500*1350mm + 1800*530mm

Detailed Images

1. Edgebander

- Double motors traveling on linear guides for end-trimming

- Six rollers pressure zone. One big precision roller and five small ones to make sure the edge is pressed seamlessly to the working piece.

- Temperature adjustable by control modules.

- Enable actions start by encoder instead of limited switch.

2. Power Roller line

The panel is transported by the power roller conveyor with high speed, improves transmission efficiency.

3. Bend Roller

The bend roller conveyor uses a cone roller as a carrier to smoothly transport articles along the curve. The bend roller conveyor is used in conjunction with the linear conveyor to achieve very good corner conveying. The cargo can maintain its relative position during the conveying process and realize synchronous conveying.

Sample

Application:

The raw materials used by the panel furniture manufacturers are mainly for particleboard, MDF and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips.

Company Information

Company introduction

- EXCITECH is a company specializing in the development and manufacture of automated woodworking equipment. We are in the leading position in the field of non-metallic CNC in China. We focus on building intelligent unmanned factories in the furniture industry. Our products cover plate furniture production line equipment, full range of five-axis three-dimensional machining centers, CNC panel saws, boring and milling machining centers, machining centers and engraving machines of different specifications. Our machine are widely used in panel furniture, custom cabinet wardrobes, five-axis three-dimensional processing, solid wood furniture and other non-metal processing fields.

- Our quality standard positioning is synchronized with Europe and the United States. The whole line adopts standard international brand parts, cooperates with advanced processing and assembly processes, and has strict process quality inspection. We are committed to providing users with stable and reliable equipment for long-term industrial use. Our machine are exported to more than 90 countries and regions, such as United States, Russia, Germany, the United Kingdom, Finland, Australia, Canada, Belgium,etc.

- We are also one of the few manufacturers in China that can carry out the planning of professional intelligent factories and provide related equipment and software. We can

provide a series of solutions for the production of panel cabinet wardrobes and integrate customization into large-scale production.

Sincerely welcome to our company for field visits.

CE Certificate

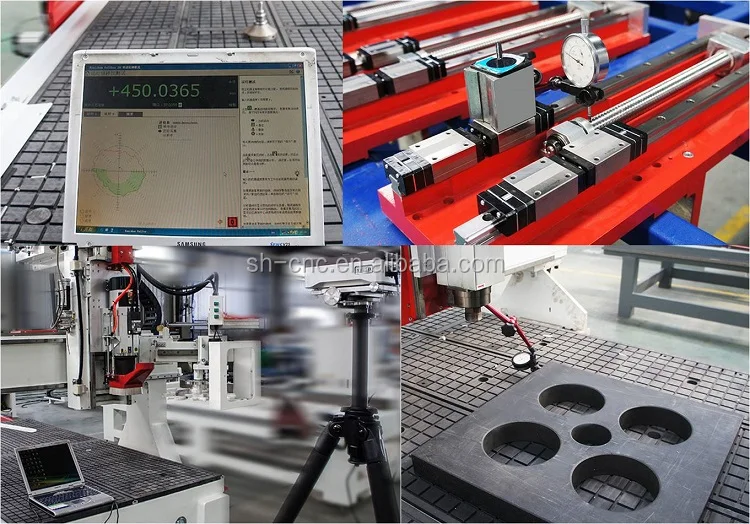

Quality Inspection

Machining workshop

We have our own machining workshop, a total of 5 gantry five-sided milling, each special machine for special use.

Side arms, beams, Z-axis skateboards, machine beds are specially processed by different equipment to guarantee high precision of the machine.

Packaging & Shipping

The cnc center is to be packed with plastic sheet for cleaning and damp proofing.

Fasten the cnc machine into the wood case for safety and against clashing.

Transport the wood case into the container.